knowledgebase

Lambda 001 Motor Design

Part 2: Examining the traditional options

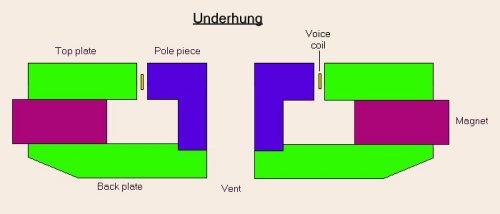

To accomplish the above only one motor design comes close immediately, the Underhung. The Underhung uses a tall gap plate with a short coil. The flux is quite evenly distributed throughout the gap

leading to a very flat BL curve while the coil is operating within it's linear range.

To accomplish the above only one motor design comes close immediately, the Underhung. The Underhung uses a tall gap plate with a short coil. The flux is quite evenly distributed throughout the gap

leading to a very flat BL curve while the coil is operating within it's linear range.

(1) The flux level is the same as long as the VC stays in the gap

(2) There is a lot of steel to absorb the heat from the coil.

(3) No matter where the VC is in the gap the steel core is the same, forcing its inductance to stay linear with excursion.

However, has 3 problems to consider as well

(1) For any significant power handling the VC diameter must increase. This increases overall inductance and significantly increases cost.

(2) It needs a much larger motor structure vs an overhung as only a portion of the flux in the gap is being used at any given time. Again this leads to more cost.

(3) As the coil leaves the gap the Bl drops very quickly and the driver immediately compresses the output. For this reason you need to keep the driver operating within its excursion limits

(4) And most importantly, WE STILL CAN NOT KEEP THE FLUX FROM MOVING IN THE GAP.